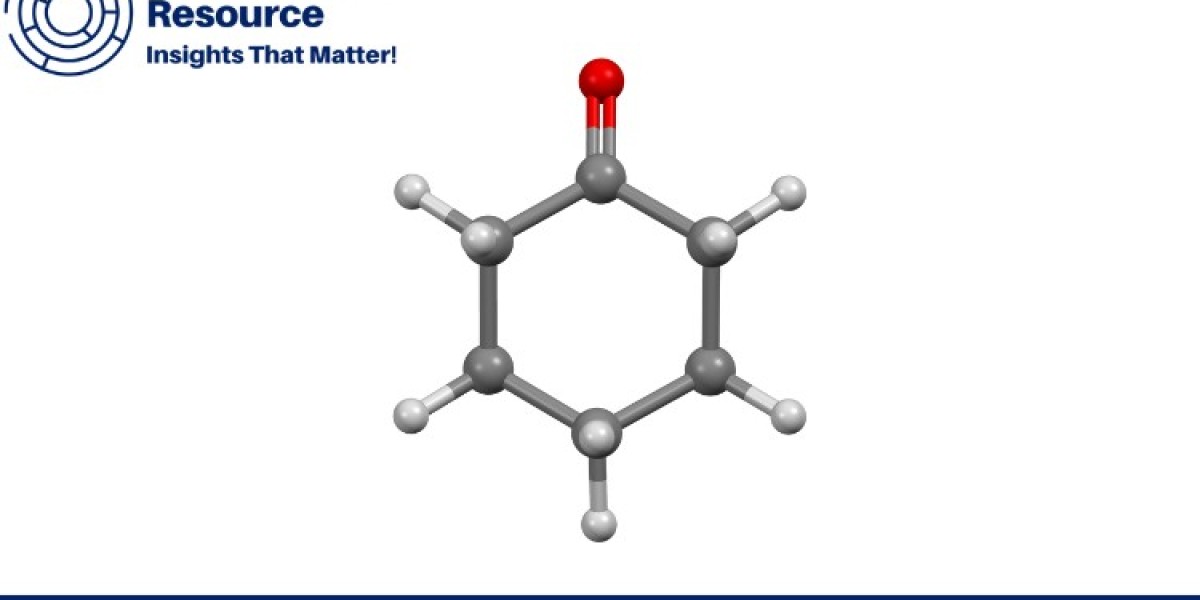

Cyclohexanone is a crucial chemical intermediate used extensively in producing nylon, as well as in the manufacturing of paints, varnishes, and other products in the chemical and industrial sectors. For companies involved in its production or distribution, understanding cyclohexanone production costs is essential to optimize resources, maintain competitiveness, and meet market demands. At Procurement Resource, we provide detailed insights into cyclohexanone production costs, helping businesses make data-driven and strategic decisions.

Why Cyclohexanone is Important

Cyclohexanone is a versatile compound primarily used to produce adipic acid and caprolactam—key ingredients in nylon production. It also serves as a solvent in industries ranging from coatings and adhesives to plastics and rubber. With a growing demand for nylon and other polymer products, understanding cyclohexanone production costs is critical for chemical companies seeking to manage expenses effectively and ensure consistent supply.

Request a Free Sample for Cyclohexanone Production Cost Report - https://www.procurementresource.com/production-cost-report-store/cyclohexanone/request-sample

Breaking Down Cyclohexanone Production Costs

Cyclohexanone production involves processes like the oxidation of cyclohexane or the hydrogenation of phenol, which require raw materials, energy, and specialized equipment. Production costs vary depending on factors such as raw material prices, energy requirements, labor, and regulatory compliance. Below is a detailed breakdown of the main cost components in cyclohexanone production:

1. Raw Material Costs

The primary raw materials used in cyclohexanone production are cyclohexane and phenol. Cyclohexane is often derived from crude oil, so its cost is subject to fluctuations in global oil markets. Alternatively, the hydrogenation of phenol is another common method, where phenol prices are influenced by supply-demand dynamics in the chemical sector.

Raw material costs constitute a significant portion of cyclohexanone production expenses, making it crucial for companies to secure reliable and cost-effective sources. Any changes in the prices of cyclohexane or phenol directly impact production costs, so companies must actively monitor these prices and establish stable supplier relationships.

2. Energy Costs

Cyclohexanone production is energy-intensive, requiring substantial amounts of electricity and heat to maintain high temperatures and pressures in reactors. Energy costs are closely linked to fuel and electricity prices, which can fluctuate due to market demand, geopolitical factors, and seasonal changes.

For cyclohexanone producers, optimizing energy usage through efficient technologies and equipment is essential for managing these costs. By investing in energy-efficient processes, companies can reduce their overall energy expenses and improve production sustainability.

3. Labor and Operational Costs

Labor costs in cyclohexanone production include wages for skilled workers, chemists, and technicians involved in operating equipment, monitoring quality, and managing safety protocols. Operational costs also cover facility maintenance, safety training, and quality control.

Read the Full Cyclohexanone Production Cost Report - https://www.procurementresource.com/production-cost-report-store/cyclohexanone

In regions with higher wages, labor costs can make up a substantial portion of the overall production expenses. As automation becomes more prevalent in chemical manufacturing, companies are increasingly investing in automated systems to streamline operations, reduce labor costs, and improve production efficiency.

4. Technological Advancements and Maintenance

Advanced technology in cyclohexanone production allows for greater efficiency, higher yield, and lower waste. However, adopting and maintaining these technologies require capital investments, and equipment must be maintained to ensure consistent product quality and operational reliability.

Investing in advanced equipment and technologies often involves high upfront costs, but they offer long-term benefits by reducing energy consumption, increasing production speed, and minimizing waste. Regular maintenance is essential to avoid costly downtime and ensure smooth operations.

5. Environmental and Regulatory Compliance

Chemical production is subject to strict environmental and regulatory standards, particularly regarding emissions, waste management, and chemical safety. Compliance with these regulations can add to production costs, as companies need to invest in waste treatment systems, emissions control, and environmental audits.

Adherence to environmental standards is essential to avoid fines, product recalls, and reputational damage. Many cyclohexanone producers are also investing in sustainable practices and cleaner production methods, which, while initially costly, help align the company with environmental standards and consumer expectations for eco-friendly practices.

How Procurement Resource’s Cyclohexanone Production Cost Reports Can Benefit You

At Procurement Resource, we provide comprehensive Cyclohexanone Production Cost Reports that simplify the complexities of production costs into actionable insights. Our reports offer a thorough analysis of every aspect of cyclohexanone production, helping businesses understand cost factors and identify areas for optimization.

Ask an Analyst - https://www.procurementresource.com/production-cost-report-store/cyclohexanone/ask-an-analyst

Our Reports Offer:

- Detailed Cost Breakdown: From raw materials and energy to labor and environmental expenses, our reports provide a clear and thorough breakdown of all factors influencing cyclohexanone production costs.

- Real-Time Data: The chemical market is constantly evolving, and our reports include up-to-date data and forecasts to help you make informed decisions based on the latest trends.

- Price Trends and Analysis: We track price trends for cyclohexane, phenol, and other production costs, allowing businesses to develop effective procurement strategies and anticipate changes.

- Benchmarking and Comparison: Compare your production costs with industry standards to identify areas for potential savings or efficiency improvements.

- Procurement Insights: Our reports offer practical procurement strategies, helping you manage your cyclohexanone supply chain more effectively, reduce costs, and secure reliable suppliers.

Key Benefits of Cyclohexanone Production Cost Reports

Enhanced Cost Control: By understanding each factor contributing to cyclohexanone production costs, companies can identify areas for cost reduction and implement more efficient processes.

Improved Budget Planning: Detailed data on cost drivers and price trends allow for accurate forecasting of cyclohexanone-related expenses, ensuring budgets are aligned with market conditions.

Competitive Advantage: Staying informed about industry trends and production costs provides companies with a competitive edge, enabling them to implement cost-saving measures and remain profitable.

Sustainability and Compliance: Our reports help companies assess the costs of regulatory compliance and explore sustainable production methods that align with industry standards and consumer expectations.

Stay Ahead of Market Trends with Procurement Resource

By partnering with Procurement Resource, you’ll gain access to valuable insights that keep you at the forefront of the cyclohexanone market. Our Cyclohexanone Production Cost Reports are designed to simplify procurement, improve supply chain management, and support your decision-making with actionable insights.

We understand that each business has unique needs, which is why our reports are customizable to meet your specific objectives. Whether you’re focused on managing production costs, exploring sustainable production practices, or navigating complex regulatory requirements, our team of expert analysts is here to provide guidance at every step.

Request Your Free Sample Report Today

Ready to optimize your cyclohexanone production and procurement processes? Request a free sample report from Procurement Resource and access the insights you need to manage cyclohexanone-related expenses, improve efficiency, and stay competitive.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/cyclohexanone/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA copyright: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA