In today's industrial landscape, energy efficiency is more crucial than ever. One effective solution is the use of industrial-grade LED vapor tight lighting for energy conservation. This type of lighting not only enhances visibility in challenging environments but also significantly reduces energy consumption. Let’s delve deeper into the advantages of these lighting fixtures.

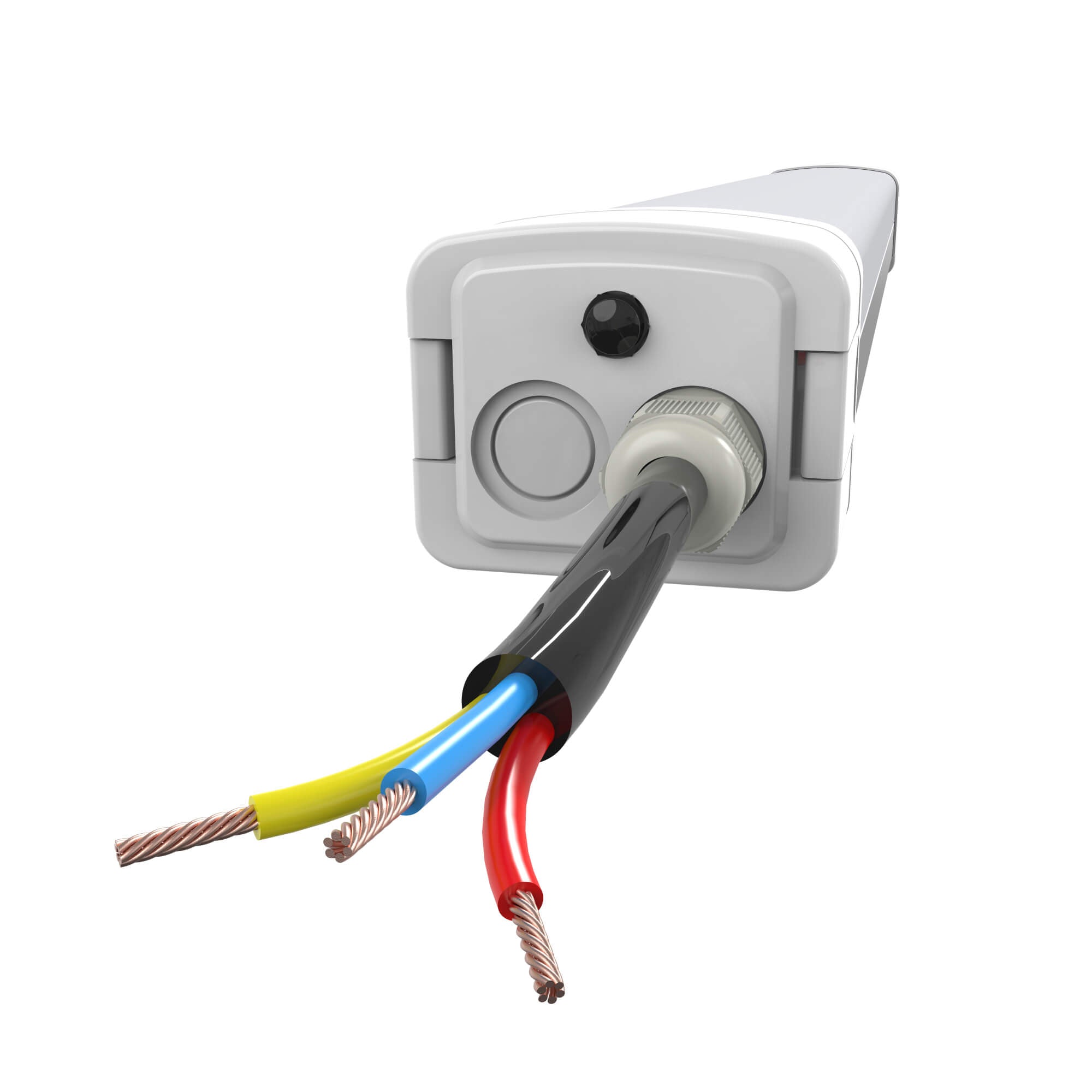

Understanding Industrial-Grade LED Vapor Tight Lighting

Industrial-grade LED vapor tight lighting is specifically designed to withstand harsh conditions, including moisture, dust, and extreme temperatures. These fixtures are ideal for warehouses, manufacturing plants, and outdoor applications where traditional lighting may fail. But what makes them a preferred choice for energy conservation?

Energy Efficiency and Longevity

One of the primary benefits of using industrial-grade LED vapor tight lighting for energy conservation is their energy efficiency. LEDs consume significantly less power compared to traditional incandescent or fluorescent lights. For instance, while a standard bulb may use 60 watts, an equivalent LED can provide the same brightness with only 10-15 watts. This reduction in energy consumption leads to lower electricity bills and a smaller carbon footprint.

- Lower energy costs

- Reduced maintenance expenses due to longer lifespan

- Less frequent replacements, minimizing waste

Durability and Performance

Another advantage of industrial-grade LED vapor tight lighting is their durability. These fixtures are built to last, often featuring robust materials that resist corrosion and impact. This durability ensures consistent performance even in the most demanding environments. Wouldn't it be beneficial to invest in lighting that not only saves energy but also withstands the test of time?

Applications in Various Industries

The versatility of industrial-grade LED vapor tight lighting for energy conservation makes it suitable for a wide range of applications. From food processing facilities to outdoor parking lots, these lights can be installed in various settings. Here are some common applications:

- Manufacturing plants

- Food and beverage processing

- Cold storage facilities

- Outdoor areas and parking lots

Conclusion: A Smart Investment for the Future

In conclusion, the adoption of industrial-grade LED vapor tight lighting for energy conservation is a smart investment for any industrial facility. Not only do these fixtures provide significant energy savings, but they also enhance safety and productivity. As industries continue to prioritize sustainability, making the switch to LED technology is a step in the right direction.

For those interested in exploring options for industrial-grade LED vapor tight lighting, consider visiting  for a range of high-quality products designed to meet your energy conservation needs.

for a range of high-quality products designed to meet your energy conservation needs.